How does a soft, perishable banana, with its high moisture content and short shelf life, transform into a stable, versatile, and flavourful powder? The journey from fruit to a fine, free-flowing powder is a marvel of modern food processing. For food manufacturers and importers, understanding this process is key to sourcing a high-quality, consistent, and effective ingredient.

Dehydrated Banana Powder is more than just a convenience; it’s a precisely engineered product. As an experienced Indian banana powder exporter, we believe in transparency. This guide peels back the curtain on the meticulous, multi-stage process required to create this essential food ingredient.

Step 1: The Foundation – Meticulous Raw Material Selection

The quality of the final powder is determined before the process even begins. It starts with the selection of the right raw material. This is a critical step where the end-use of the powder is the deciding factor.

For Sweetness & Flavor (Ripe Banana Powder): To create a powder that functions as a natural sweetener and flavouring agent, fully mature, yellow bananas with the right Brix (sugar) level are chosen. This ensures a rich, authentic banana taste, perfect for cereals, baby food, and bakery mixes.

For Functional Fiber (Raw Banana Flour): To create a starchy, gluten-free flour high in resistant starch, unripe green bananas are used. This results in the product commonly known as banana flour.

Only fresh, high-quality fruits, free from blemishes and defects, are selected to move to the next stage.

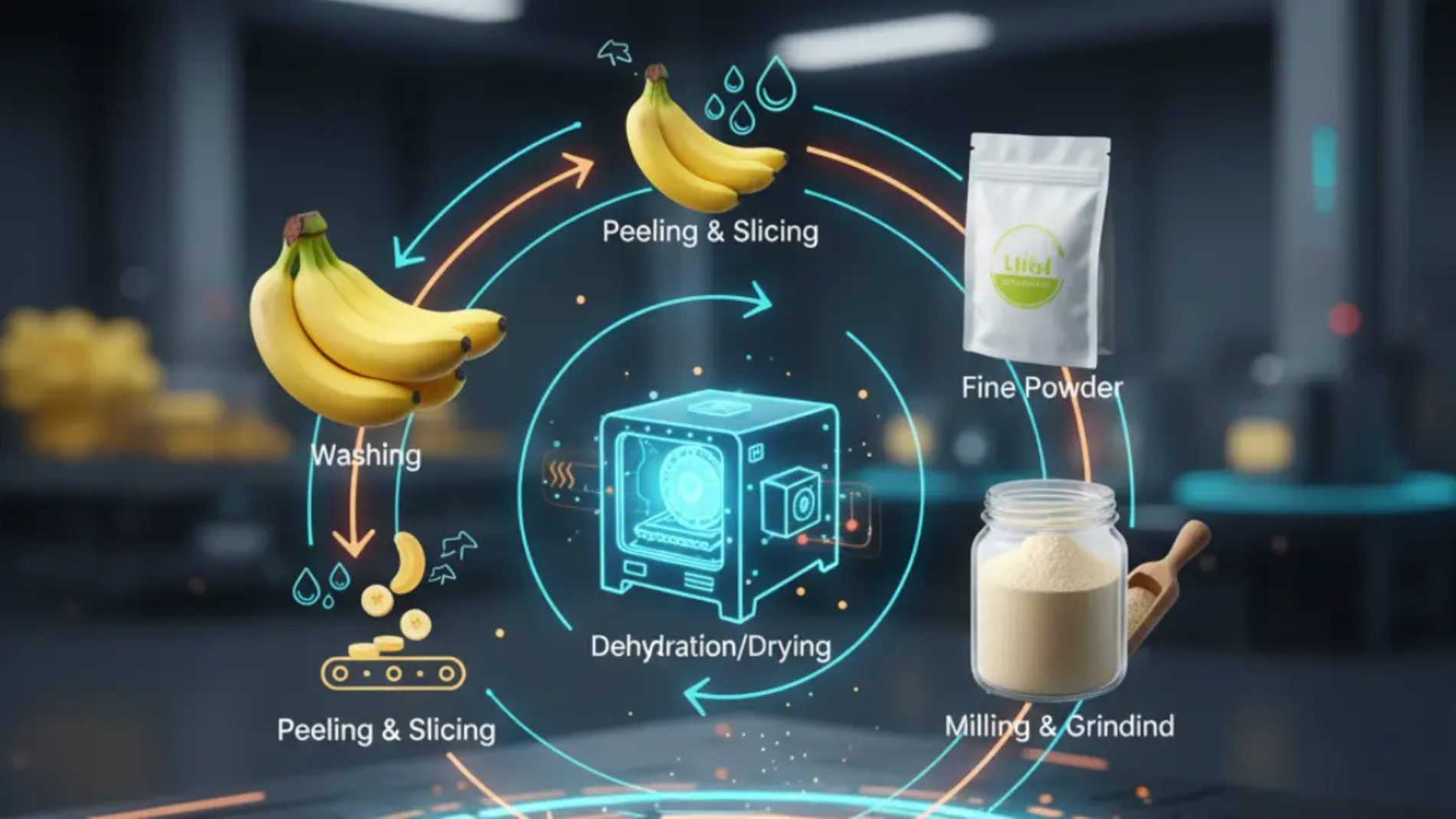

Step 2: Preparation – Peeling, Slicing, and Pre-Treatment

Once the right bananas are selected, the preparation phase begins. This stage is crucial for ensuring the final product’s quality and colour.

The bananas are washed to remove any surface impurities and then carefully peeled. They are then sliced into uniform thin pieces or turned into a liquid purée. Uniformity is key here, as it ensures that every piece dries at the same rate. In some cases, a natural anti-browning agent, such as a citric or ascorbic acid solution, may be used to prevent oxidation and maintain the powder’s light, creamy colour.

Spice Up Your Business with Authentic Indian Flavors

Import and Export Excellence from India!

Step 3: The Heart of the Process – Advanced Dehydration Methods

This is the most critical stage, where water is removed to create a shelf-stable product. The two primary industrial methods for producing high-quality dehydrated banana powder are Spray Drying and Drum Drying.

Spray Drying (The Gold Standard for Powders): This is the most advanced and widely used method for premium powders. The banana purée is atomized (sprayed as a fine mist) into a chamber of hot air. The water evaporates almost instantly, and the fine, dry powder particles fall to the bottom for collection. Spray-dried banana powder is prized for its very fine particle size, high solubility, and excellent preservation of flavour and nutrients.

Drum Drying: In this method, the banana purée is spread as a thin film onto the surface of a large, heated rotating drum. The heat dries the purée, which is then scraped off as a thin sheet or flakes. These flakes are then milled into a powder. While effective, this method can sometimes impart a slightly more “cooked” flavour due to direct contact with the hot surface.

Step 4: Milling and Sieving – Achieving the Perfect Texture

After dehydration, the product is not yet a perfect powder. It is then milled to break down any larger particles and create a uniform, fine consistency.

Following milling, the powder is passed through a series of sieves or screens to classify it according to particle size (mesh). This is a critical quality control step that ensures the final product meets the exact banana powder specifications required by the manufacturer, whether it’s for a smooth beverage mix or a textured bakery application.

Step 5: Final Quality Control and Export-Grade Packaging

The final stage is a rigorous quality check. Samples from the finished batch are sent to a lab to verify key parameters. This is where a trusted banana powder supplier demonstrates their commitment to quality. The results are presented in a Certificate of Analysis (COA), which confirms:

Moisture Content: Must be very low (typically below 8%) for a long shelf life.

Microbiological Safety: Ensuring the product is free from harmful bacteria.

Purity: Confirming it is 100% banana powder.

Finally, the powder is packed into multi-wall paper or HDPE bags with a heat-sealed inner poly-liner. This packaging is designed to protect the hygroscopic (moisture-absorbing) powder during its long export journey.

From a carefully selected fresh fruit to a precisely engineered powder, the process is a testament to the power of food science in delivering nature’s goodness in a stable, reliable, and highly functional format.

Spice Up Your Business with Authentic Indian Flavors

Import and Export Excellence from India!

Frequently Asked Questions (FAQs)

1. What is the difference between spray-dried and drum-dried banana powder?

Spray-dried banana powder is generally a finer, more soluble powder, making it ideal for beverages and instant mixes. Drum-dried can result in a slightly coarser flake or powder and is also widely used, but spray-drying is often considered the premium method for fine powders.

2. Does the dehydration process destroy the nutrients in the banana?

Modern, controlled drying methods like spray-drying are very fast and are designed to minimize heat exposure, which helps to preserve the majority of the banana’s natural vitamins and minerals, especially potassium.

3. What is the typical shelf life of dehydrated banana powder?

When processed to a low moisture content and stored in its original, unopened packaging in a cool, dry place, it typically has a shelf life of 12 to 18 months.

4. What does “mesh size” mean for banana powder?

Mesh size refers to the particle size of the powder, indicating how fine it is. A higher mesh number (e.g., 100 mesh) means a finer powder, which is better for smooth-textured products.

5. Is dehydrated banana powder the same as banana flour?

The terms are often used interchangeably, but there’s a key difference. Banana flour is almost always made from unripe, green bananas (it’s starchy, not sweet). Dehydrated banana powder is a broader term that can refer to powder made from either ripe or raw bananas.

6. Can dehydrated banana powder be certified organic?

Yes, absolutely. Sourcing certified organic powder is a popular choice, especially for the baby food and health food industries, ensuring the bananas were grown without synthetic pesticides.

7. Why is sourcing from India a good choice?

India is one of the world’s largest producers of bananas. This provides a massive, reliable supply of raw materials. Experienced Indian exporters have sophisticated manufacturing processes and a deep understanding of the quality standards required for the global market.

8. How can I be sure of the quality I’m receiving?

Always request a batch-specific Certificate of Analysis (COA) from your supplier. This is your scientific guarantee that the product meets the required specifications for moisture, purity, and safety.

About us

We bridge the gap between local producers and global markets, ensuring seamless trade facilitation with exceptional quality and reliability. We provide quick delivery services with customized packaging with all approval of International Certificates (Spices board India, MSME, IEC, fssai, FIEO, APEDA, EU certification, FDA and Many More)

Contact us

Shop No. 3, Ganesh Prestige Sr. No. 2/15, Near Laxmi Jewellers, Dhanakawadi, Pune – 411043, Maharashtra INDIA.

Call On

+91 9545205050

+91 9822422584

Leave A Comment