In the world of food ingredient sourcing, consistency is the foundation of brand trust. Your customers expect your signature soup mix, snack seasoning, or marinade to taste the same every single time. But what if the Onion Powder in one batch is less pungent than the last? What if it clumps, burns, or behaves differently in your formulation?

The culprit is often one of the industry’s biggest hidden problems: adulteration. To cut costs, some suppliers will bulk out their bulk onion powder with cheap fillers. For a food manufacturer, sourcing an impure product isn’t just a minor issue—it’s a critical failure that can damage your product, your reputation, and your bottom line.

As a leading onion powder supplier in India, we operate on a “Purity Promise.” We believe an educated buyer is our best customer. This guide will teach you exactly how to ensure the Onion Powder you source is 100% pure, potent, and filler-free.

Why Purity is a Non-Negotiable for Food Manufacturers

Sourcing impure onion powder is far more than a simple quality issue; it’s a significant business risk.

Flavor Dilution and Inconsistency: The most common fillers are starches (like corn, rice, or tapioca) and cheap flours (like wheat). These ingredients have no onion flavor. This dilutes the pungency, forcing you to use more powder to achieve the same taste profile, which completely throws off your formulation and increases your cost-in-use.

Product and Batch Failure: Fillers react differently to heat and liquid. An undeclared starch can scorch during a heating process, imparting a burnt taste. It can also cause unexpected thickening or clumping in sauces and marinades, ruining the texture of your final product.

Allergen and Legal Risks: If the filler is an undeclared allergen like wheat or soy flour, the consequences can be catastrophic. This can lead to expensive product recalls, legal action, and an irreversible loss of consumer trust.

The "How-To": Your 5-Point Purity Verification Checklist

True export quality onion powder is 100% dehydrated onion. Here is how you can verify that’s what you’re getting.

1. Scrutinize the Supplier and Their Source A trustworthy supplier will be transparent. Ask them about their raw material. Are they using high-quality Nashik onions, known for their high pungency? Or are they using low-grade byproducts? A supplier who is proud of their source (like the dehydrated white onion from India’s best growing regions) will be open about it.

Spice Up Your Business with Authentic Indian Flavors

Import and Export Excellence from India!

2. Demand a Certificate of Analysis (COA) This is the most important document in B2B food ingredient sourcing. Never place a bulk order without a batch-specific COA. This lab report is your proof of quality. It should, at a minimum, include:

A purity statement (e.g., “100% Dehydrated Onion”).

A microbiological analysis (confirming it’s free from pathogens).

Moisture content (crucial for shelf life and preventing clumping).

3. Conduct a Physical and Sensory Test Your own senses are a powerful tool. When you receive a sample, test it immediately:

Look: Pure White Onion Powder should be a creamy, off-white colour. A stark, paper-white colour is a major red flag for starch fillers.

Feel: Rub it between your fingers. It should feel fine and slightly abrasive, like a very fine grain. If it feels exceptionally soft, silky, or “powdery” (like talc), be suspicious.

Taste: The flavour should be intensely pungent, sharp, and unmistakably onion. A starchy, chalky, or overly salty taste means it has been adulterated.

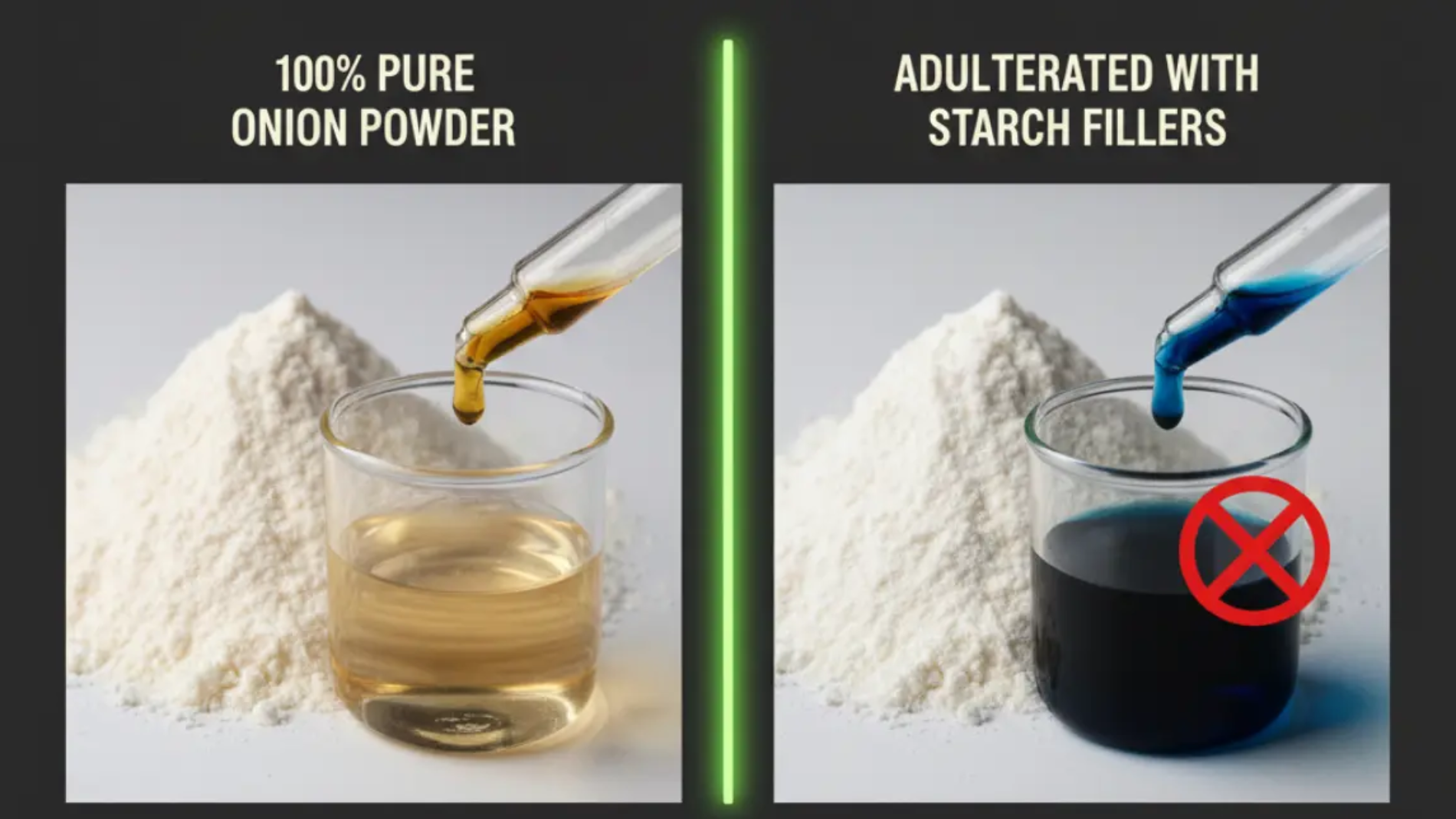

4. Perform the Simple Iodine Test for Starch This is a simple, effective test you can do in your own facility in 30 seconds.

Place a small amount of the onion powder in a dish.

Add a few drops of a standard iodine solution (tincture of iodine).

The Result: Pure onion powder will not react, or will turn a light brownish-yellow. If the powder turns dark blue or black, it has been adulterated with starch. This simple test can save you from a very costly mistake.

5. Be Wary of “Too Good to Be True” Pricing Everyone wants a good price, but in the spice trade, an abnormally low price is the #1 warning sign. The cost of pure, high-pungency dehydrated white onion is stable. A supplier offering bulk onion powder at a price far below the market average is almost certainly cutting costs, and the most common way to do that is with fillers.

The Purity Promise: Your Foundation for a Quality Product

By focusing on purity, you are not just buying an ingredient; you are protecting your brand. When you partner with a supplier who can provide verifiable, consistent, filler-free onion powder, you are building your product on a foundation of quality. This ensures your formulations work perfectly every time, and your customers get the consistent, high-quality taste they expect.

Frequently Asked Questions (FAQs)

1. What is the most common filler used in onion powder?

The most common adulterants are starches, such as corn starch, rice flour, or tapioca starch, because they are cheap, white, and easily blend in.

2. Is an anti-caking agent considered a filler?

Not necessarily, but it must be declared. A small, declared amount (typically <2%) of a food-grade anti-caking agent (like Silicon Dioxide) is acceptable in the industry to ensure flowability. A “filler,” by contrast, is an undeclared ingredient used to add weight and reduce cost.

3. What is the correct color of pure White Onion Powder?

It should be a natural-looking creamy or off-white. A brilliant, stark-white powder is a strong indication that it has been mixed with a bleached starch filler.

4. Why is Indian onion powder so pungent? India, particularly the Nashik region, is famous for growing onion varieties that have a high pungency (high sulfur content). When these onions are dehydrated, that potent flavour is concentrated, creating a superior powder.

5. How does purity affect the shelf life of onion powder?

Impure powders, especially those with starchy fillers, can be more hygroscopic (they absorb moisture from the air). This leads to rapid caking, clumping, and potential microbial growth, shortening the product’s shelf life.

6. Does the “iodine test” really work?

Yes, it is a simple and reliable chemical test. Iodine reacts with starch and turns it a deep blue-black colour. It is one of the fastest ways to check a new supplier’s sample for the most common type of adulteration.

7. What’s the difference between onion powder, granules, and kibbled?

The only difference is the particle size (mesh). Powder is a fine grind, granules are coarser (like sand), and kibbled is even larger (minced or chopped pieces). All should be 100% pure onion.

8. How can I guarantee purity without testing every batch?

The key is to build a long-term relationship with a trusted, transparent onion powder supplier. A reliable partner will have their own multi-step quality control process and will always provide a batch-specific COA as a standard practice.

About us

We bridge the gap between local producers and global markets, ensuring seamless trade facilitation with exceptional quality and reliability. We provide quick delivery services with customized packaging with all approval of International Certificates (Spices board India, MSME, IEC, fssai, FIEO, APEDA, EU certification, FDA and Many More)

Contact us

Shop No. 3, Ganesh Prestige Sr. No. 2/15, Near Laxmi Jewellers, Dhanakawadi, Pune – 411043, Maharashtra INDIA.

Call On

+91 9545205050

+91 9822422584

Leave A Comment